Preparations for the major overhaul of VA10 have been completed. Following an intensive planning phase, switch cabinet construction, and successful integration testing of the new switchgear and control systems, a total of 144 switch cabinets, various consoles, motors, and attachments were transported to the storage site at Thyssenkrupp Rasselstein GmbH.

At the beginning of January 2026, KERN Industrie Automation GmbH will begin renovations at Andernach plant, which we will continue to report on here.

+++ Day 3 +++

We are starting day 3 of the conversion and the team from Kern Industrie Automation GmbH is well on schedule. Thanks to detailed planning, the dismantling of the old switchgear is progressing well.

+++ Day 5 +++

Following the dismantling of the old switchgear, our team is now working in shifts to install the new power and control cabinets, control panels, and cabling. The first cabinets and panels are already in place.

+++ Day 8 +++

The current modernization of the VA10 does not only include the control cabinets and control stations. Along with the new converter technology, the drives are also getting new encoders, such as S-rollers 2 and 3. The planning, production, and installation of the individual encoder consoles was carried out by the mechanical engineering department at Kern Industrie Automation GmbH. As a full-service provider, we thus reduce the coordination effort between the individual fields for our customers.

+++ Day 11 +++

Our team is highly motivated as it starts day 11 of the revamping. All new power cabinets have been installed in the electrical room and the first rotary encoders have been connected. Now it’s time to start wiring the power cabinets.

+++ Day 19 +++

The cable connection work for the VA10 drives has been completed. Now it’s time for the signal check. Time to give a big shout-out to our assembly team. The team spirit is great! Thank you very much!

+++ Day 26 +++

Sustainability plays a crucial role in the energy-intensive steel industry. thyssenkrupp Rasselstein, for example, already offers packaging steel made from CO2-reduced bluemint® Steel.

Accordingly, sustainability is a key priority in the modernization of VA10. All dismantled switchgear is disassembled by our team and sorted by type so that it can be recycled to a high degree and reincorporated into the material cycle.

+++ Day 40 +++

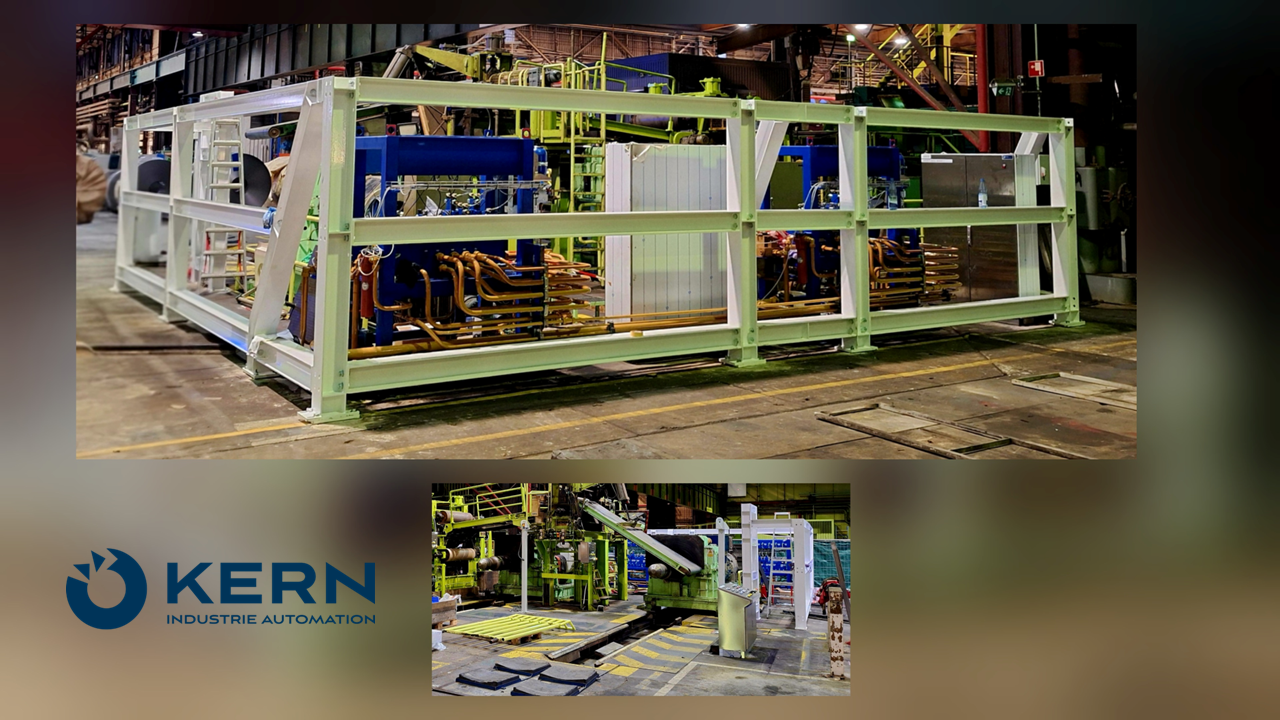

Safety for people and machines is an essential part of modernizing production facilities. To minimize the risks associated with coil handling in the entry section of the VA 10 plant, KERN Industrie Automation designed and implemented a ram protection system for this part of the plant.